Industrial Panel PC

Automotive Manufacturing

Project Overview

Our client, a leader in automotive manufacturing, required a powerful computing solution for their machine vision applications, compatible with Studio 5000 automation.

Technical Solution

- Processor: High-performance Intel Core i9 for seamless, real-time machine vision processing.

- Storage: 2TB NVMe SSD for quick data access and a 5TB SSD for additional storage.

- Display: 24-inch, 1080p screen for clear visuals.

- Power: Auto-start with 24VDC power supply for reliable, continuous operation.

- Durability: IP65-rated, solid-state design to withstand dust, moisture, and vibrations.

Client Benefits

- Enhanced Productivity: Faster processing and ample storage streamline machine vision workflows.

- Reduced Downtime: Rugged construction minimizes failure risks.

- Operational Efficiency: Integrated with Studio 5000 for seamless, efficient management.

Our tailored panel PC solution has boosted productivity and operational success, surpassing client expectations.

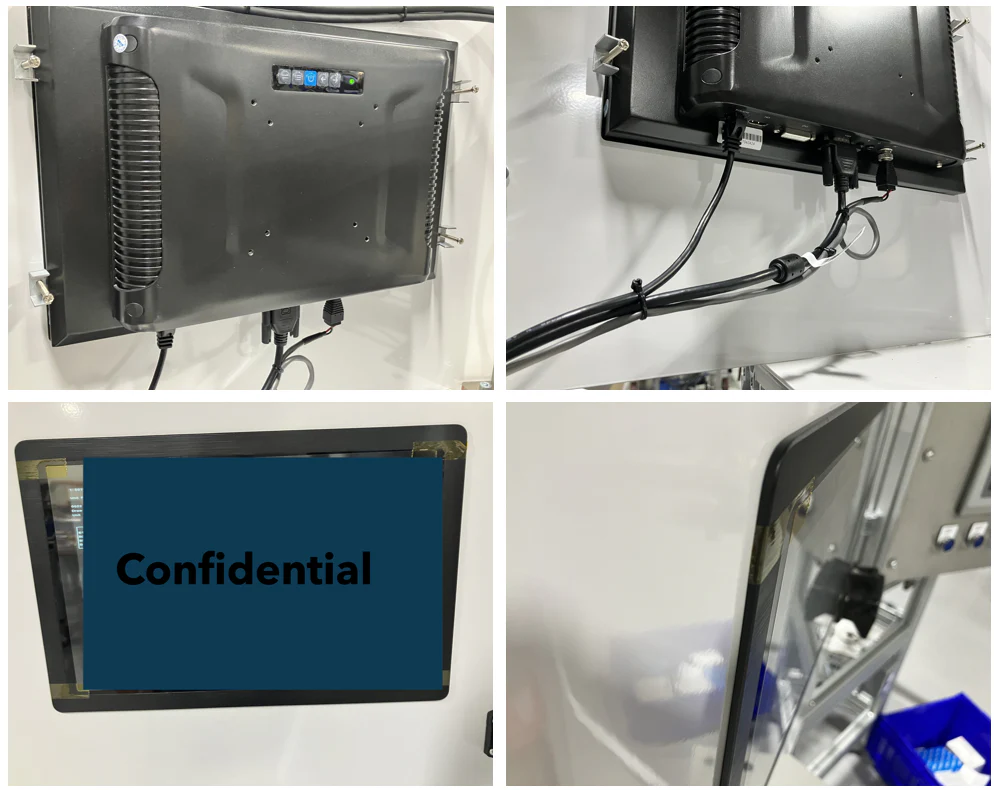

Touchscreen Monitor

Robotic Control Station

Our client required a touchscreen monitor solution for a robotic control station that supports Keyence Vision Controller operations in a challenging environment.

Key Requirements:

- Compatibility with Keyence Vision Controller touch functions.

- Sunlight-readable with optical bonding and full lamination for durability.

- Auto-brightness sensor for optimal visibility in varying light conditions.

- Automatic power-on with the Keyence Controller.

- Support for 24VDC machine supply.

- High-clarity IPS panel for a large screen display.

Result:

We provided a robust, sunlight-readable touchscreen monitor with an IPS panel, delivering seamless integration with Keyence systems and enhancing operational efficiency under diverse lighting conditions.

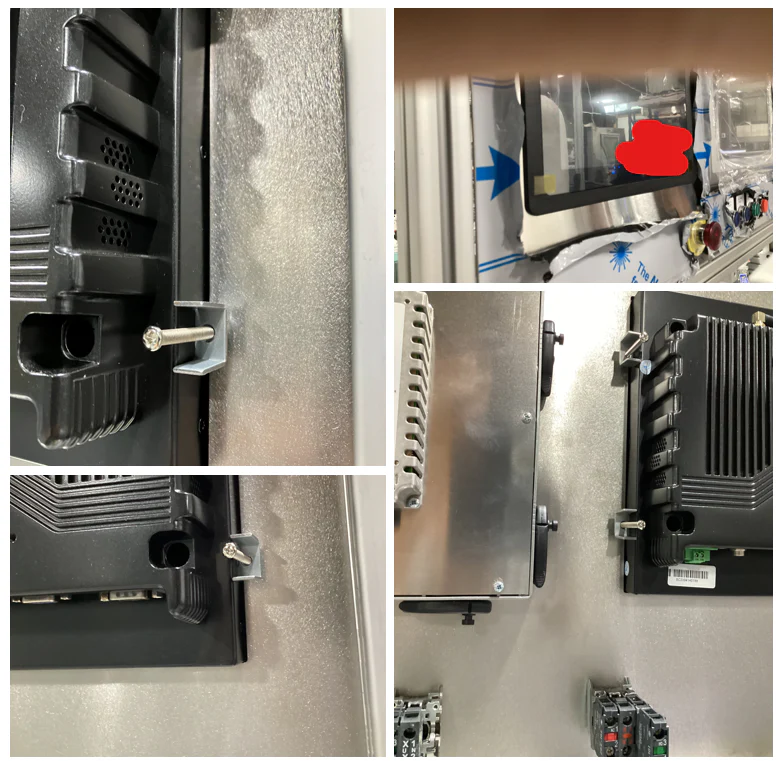

INDUSTRIAL PANEL PC

Pharmaceutical Quality Control

A leading pharmaceutical company needed an industrial panel PC for their quality control processes, optimized for seamless integration and quick deployment.

Key Requirements:

- Touchscreen: Resistive for precise touch control.

- Software Support: Compatible with FactoryTalk runtime.

- Operation: Single-click with momentary touch for motor job operations.

- Lead Time: Delivery within 1 week.

- Connectivity: Custom RS232 and RS485 connectors.

- Warranty: 5-year extended coverage.

- Operating System: Windows 10 LTSC for long-term support.

Result:

Our solution provided a reliable, efficient panel PC that met all project requirements within the tight timeframe, enhancing the client's quality control operations.

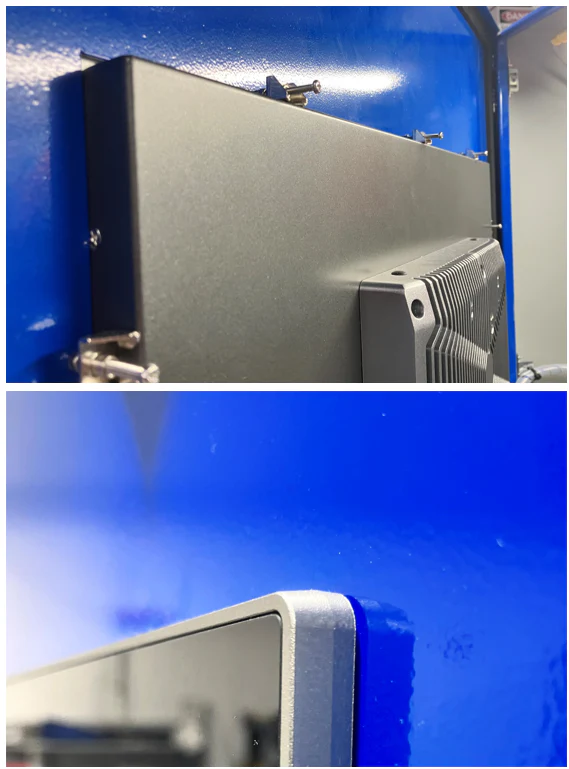

Custom Touchscreen PC

Food Processing Line Monitoring Solution

A food processing company required a specialized industrial panel PC to monitor and control production lines, with specific design and performance criteria.

Key Requirements:

- Design: Slim profile with a silver case to fit seamlessly into the existing control panel.

- Display: 24" capacitive touchscreen with 1500 nits high brightness for optimal visibility in bright environments.

- Performance: Powered by an efficient Celeron 6412 processor for reliable operation.

- Durability: IP69K-rated for water resistance, suitable for high-pressure washdowns.

- Connectivity: Dual LAN ports and WiFi for network integration.

- Power Supply: 24VDC input for easy installation.

Result:

We delivered a custom panel PC that met all specific design requirements, ensuring enhanced monitoring and control capabilities in a challenging food production environment.

Industrial PC(HMI)

Controls Engineer R&D PC

A client in R&D required an industrial panel PC capable of running FactoryTalk View and Studio 5000 with enabled touch functionality.

Key Requirements:

- Touch Control: Single-touch with right-click disabled for HMI use.

- Performance: High-speed 14th Gen Intel i7 processor, 64GB DDR5 RAM, 2TB SSD PCIe5.

- Design: Fanless system with no moving parts for reliability.

- Connectivity: WiFi and Verizon cellular capability.

- Cost: Affordable solution.

- Operating System: Windows 10 LTSC for extended support.

Result:

We delivered a powerful, cost-effective panel PC that met the client's performance needs, ensuring efficient operation in an R&D environment.